Sponsored article

How to Properly Choose a Coffee Packaging Machine for Production Specifics?

Choosing the right coffee packaging machine is crucial for ensuring product quality and production efficiency. Factors such as packaging type, efficiency, type of coffee, and budget must be considered. Adjusting the machine to the production specifics will allow optimal utilization of its capabilities and customer satisfaction. It is also worth considering an investment in an industrial coffee roaster, which will impact the quality of the final product.

Read more: The Role of Mushroom Diversity in Wholesale Offerings for Culinary Creativity

Types of Coffee Packaging Machines

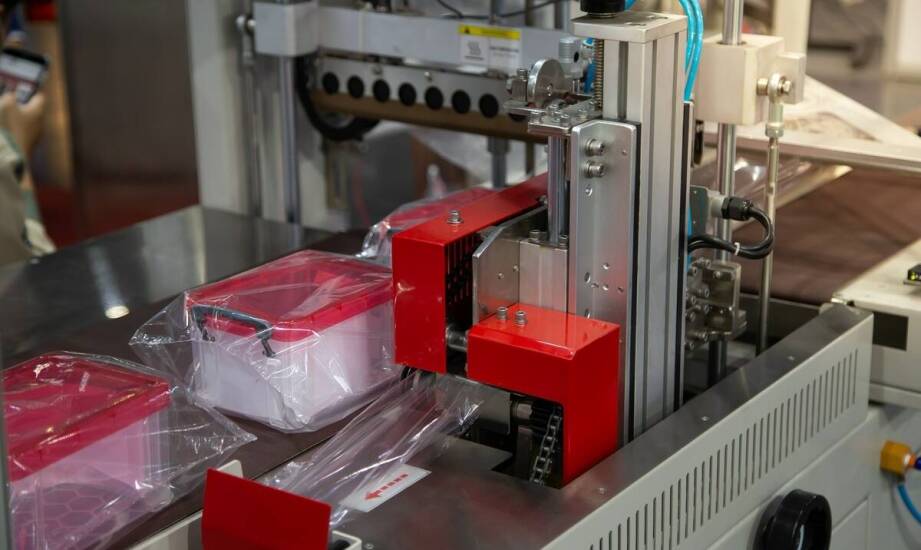

The types of machines differ in terms of functions, performance, and technology. We distinguish devices designed for packaging in bags, sachets, or containers. Each type has its application and advantages, which influence the quality of the final product. When purchasing equipment, it is important to consider the specifics of production and packaging requirements. This way, optimal results can be achieved, and customers can be satisfied.

Optimization of Machine Performance

The performance of the device is crucial for the coffee packaging machine and the efficiency of the production process. To choose the appropriate solution, it is worth analyzing the work pace and market demands. The type of packaging and the frequency of their filling should be considered. High-quality equipment is characterized by reliability and minimizes downtime. It is also advisable to use the experience of specialists offering technical and service support throughout the exploitation period. This way, the company will be able to adapt flexibly to changing production needs, which will affect operational efficiency.

Importance of Material Quality

In the context of choosing a coffee packaging machine, it is important to pay attention to various issues. A modern coffee packaging machine made of corrosion-resistant materials is characterized by greater durability and reliability, which translates into the efficiency of the entire packaging process. High-quality components ensure longer operation time and reduce the risk of failures. Therefore, it is worth investing in devices made of solid materials that guarantee reliability and efficiency for a long time.

Advantages of Automation in Coffee Packaging

The advantages of automation in coffee packaging are undeniable. Modern technologies, such as an industrial coffee roaster and automatic control systems, allow precise monitoring and control of packaging processes. This makes it possible to achieve high-quality products and minimize raw material losses. Automation also results in time and labor savings, which is particularly important for large facilities producing significant quantities of coffee.